Products

Dryers

Dehumidifying Dryers [Challenger]

Conveying Machine Function Integrated

DFC series

Challenger IV

Uses

- Engineering plastics

Applications

- Automobiles

- Electrical parts

Redefining dryers with future-proof scalability

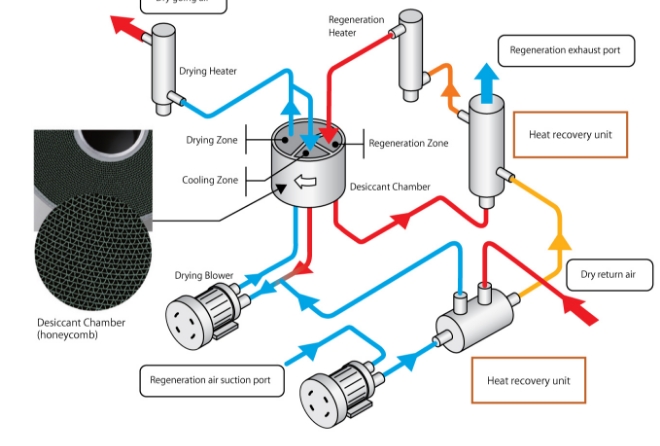

- Environmentally friendly next-generation dehumidifying dryer with reduced energy consumption through heat recovery.

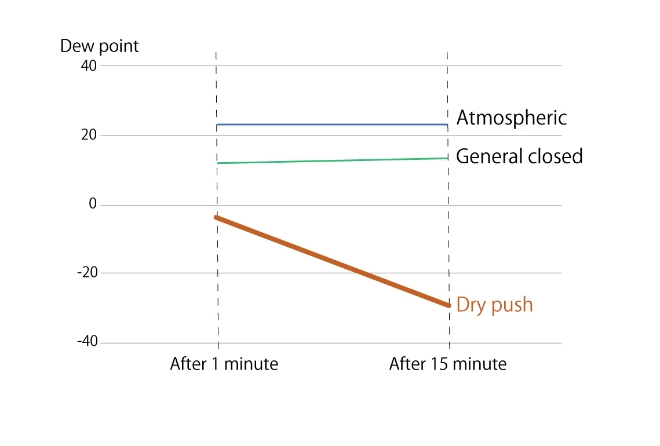

- Continuous operation type dehumidifying dryer maintains low dew point.

- Dry push transport is standard equipment. Improved maintainability due to new design. Customizable to meet various needs.

Features

-

Batch conveying of air cutting method

Since it is moved by airflow control, foreign matter is less likely to be generated compared to the conventional metal sliding type, and problems such as biting can be prevented. You can reduce the risk of material remaining in the pipe and reabsorbing moisture. -

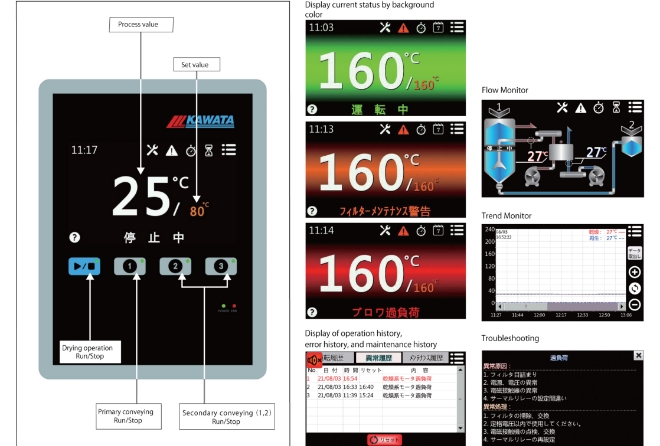

Improved maintainability

The new design places the drying, transport, and regeneration filters in a position that is easy to maintain. -

Built-in cyclone dust collector

It has also been realized in a smaller space.

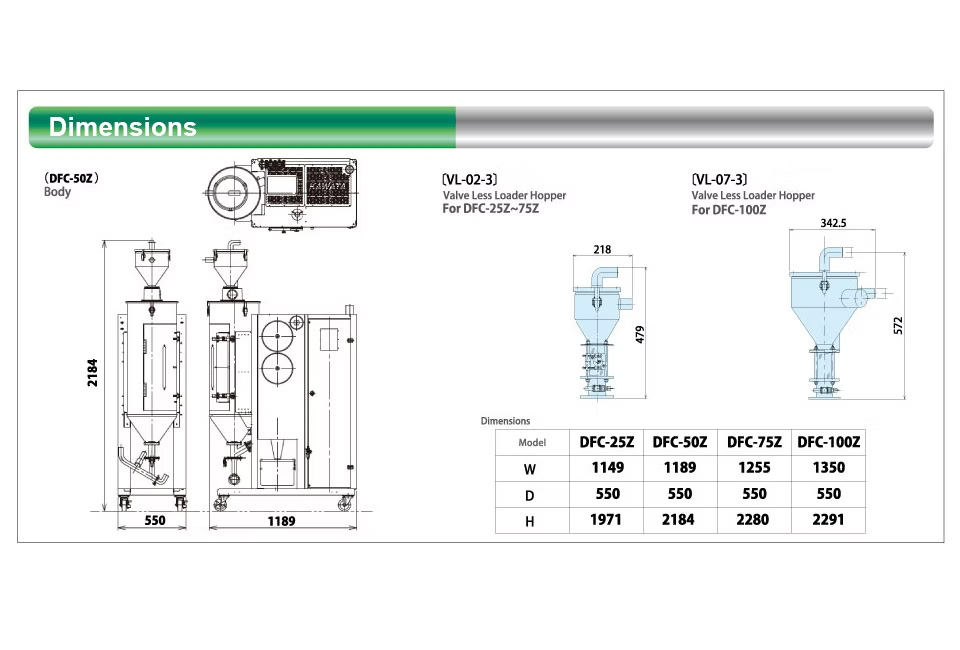

Specification

| Model | Air flow (m3/h) (50/60Hz) | Drying Temerature (°F/°C) | Dry Hopper Effective Capacity (L) |

|---|---|---|---|

| DFC-25Z | 35/45 | 140 - 320°F (60 - 160°C) Max *1 *2 | 42 |

| DFC-50Z | 50/60 | 84 | |

| DFC-75Z | 80/100 | 126 | |

| DFC-100Z | 167 | ||

| DFC-150Z | 110/120 | 250 | |

| DFC-200Z | 145/160 | 333 | |

| DFC-300Z | 220/240 | 500 |

*1: Varies depending on the physical properties of the materials used and the environment in which they are used. The stated values are based on our test environment (outside temperature 10°C to 35°C). Use this as a guideline for selection.

*2: Optional support for low-temperature drying from 60°C is available