Products

Granulators

Low speed

KGC series

G Master

Uses

- Engineering plastics

Applications

- Automobiles

- Electrical parts

Quietness, Easy cleaning, Large diameter coarse crushing blades

- Massive crushing blades OD210mm, OD319mm

Features

-

High-efficiency grinding and energy-saving design

Uses a load-blading fine crushing blade in which the blades for fine crushing are staggered. The motor load is reduced, and the material collection efficiency is improved. Coarse griding cover with minimal clearance for the blade is adopted. Suppresses the occurrence of snakeskin, etc. -

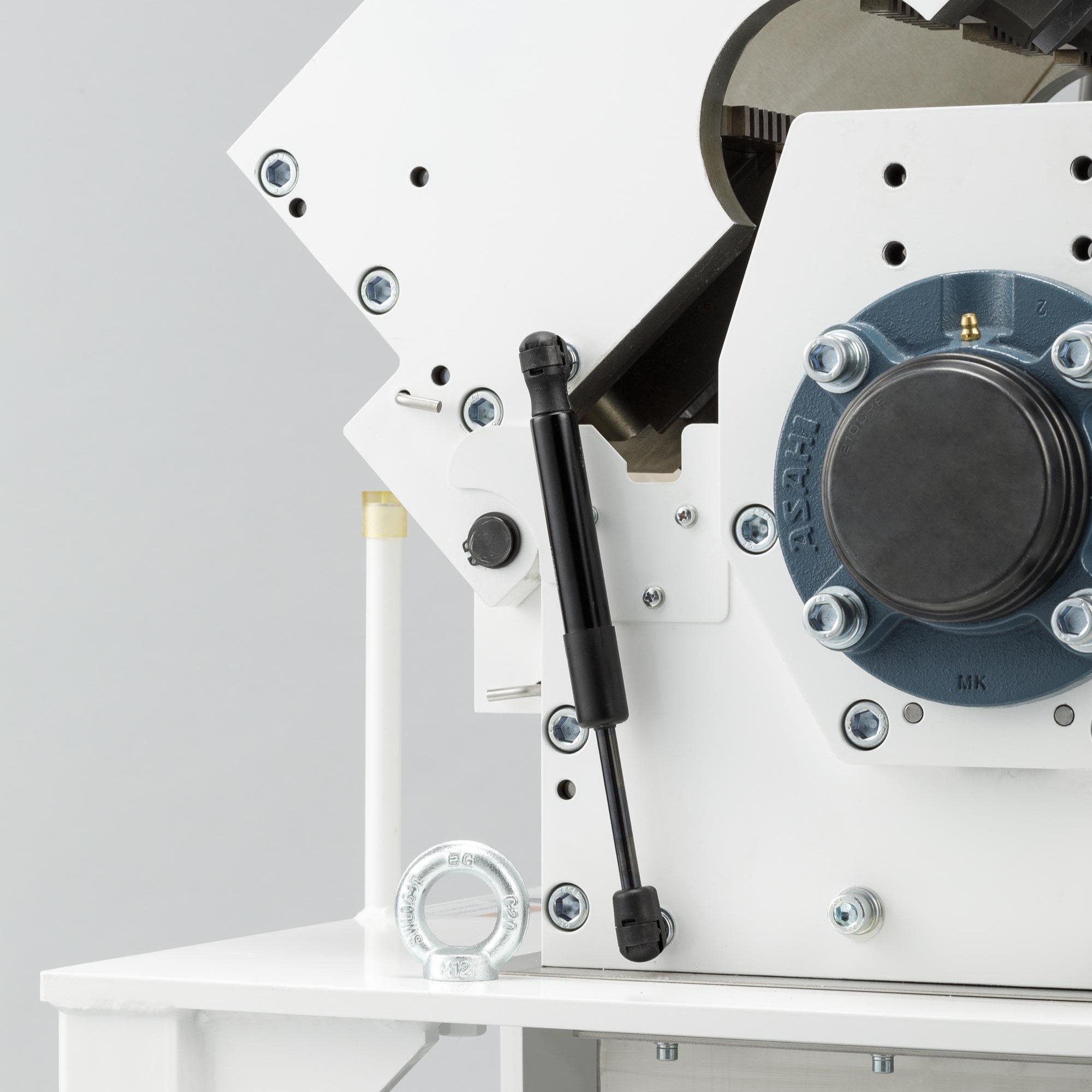

Greatly improved maintenance work

One-side access greatly increases work efficiency and reduces the burden of cleaning and blade changing work. The coarse crushing is removable! Maintainability has improved. -

Layout Free

Layout can be changed every 90 degrees in four directions. -

Emergency stop button

Detachable (magnet type) and can be attached to any position on the device body. -

Dust seal mechanism

Continuous discharge of fine power mixed in the bearing section -

Limit switch

Used in the opening / closing section of the feed hopper and the mounting section of the receiving hopper

Overflow alarm (level gauge, visual alarm, automatic stop), High frame, Receiving box, Magnetic separator, Discharge chute for surplus material

Specifications for a bag receiver

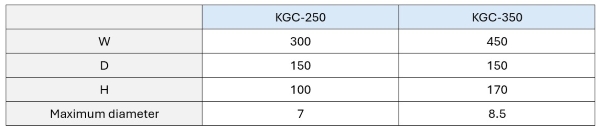

*The figures in the table are approximate values. It may be difficult to crush depending on the shape and material of the runner and the feeding condition.