CM

KAWATA-USA.COM

MAINTENANCE

Conveying hopper doubling as feeding hopper, low-profile model, and easily detachable parts for easy cleaning and maintenance Improved cleaning & maintenance much better than conventional one due to improvement of control panel location.

Automatic operation can be started or stopped, and batch counter setting can be done via this screen.※ It is possible to know if Easy mode is selected by looking for indication of ③; in Easy mode, title ③ will not be displayed.① Confirmation will be requested before shifting to Manual mode.①-1 Mode shifts to Manual mode.①-2 Closes Manual changeover confirmation screen and returns to Automatic mode.② The indicator shows that operation is in Automatic mode.③ Current recipe is shown; press this button to display Recipe pattern list.(If alarm is triggered, details of alarm will be shown here.)④ Present time is shown; press this button to shift to Clock setting screen.⑤ Transport condition is shown; the indicator illuminates during transport. Press this key to shift to Transport and mixing setting screen.⑥ Full tank conditions of individual hoppers and present value (PV) and set value (SV) of individual recipe are shown; full tank is displayed in aqua. Press the indicator to shift to Recipe pattern list screen.④⑤⑥⑫⑬⑭⑮⑪⑨⑦⑧⑯①-2①-1⑫-1⑫-2⑫-3⑧-2⑧-3⑧-1⑰②①⑱CleanRecipe③⑩Error! Use the Home tab to apply heading 1to the text you want to appear here. KAWATA MFG. CO., LTD.ACTS10017C 18⑦ Displays the feeder with which combined timer controlled weighing mode is turned on.⑧ Displays the screen in which recipe can be fine adjusted when combined timer controlled weighing mode is turned on.⑧-1 Press △(+) or ▽(-) key to increment or decrement proportion. % indicates proportion to the total.⑧-2 Press Save button to reflect changes to the recipe and switch the recipe for current operation.⑧-3 Press Provisional save button to make changes to current recipe in operation without⑨ Standard hopper in proportional control is shown. Once Automatic operation starts, feeder with this marking will be weighed first, and then other set values (SV) are changed according to actual weighed value.⑩ Conditions of secondary transport is shown.(optional)The indicator illuminates during transport and turns aqua as tank becomes full.Press the indicator to shift to Transport and Mixing setting screen.⑪ Press the indicator to shift to Fault indication screen; it blinks when alarm is triggered.⑫ Conditions of batch counter is shown; press the indicator to set batch counter conditions.⑫-1 Batch stop can be switched ON/OFF. When set to ON, operation will automatically stop after weighing number of times set in step⑫-2 Present value can be reset to return to zero (0).⑫-3 Press the indicator to display numeral keypad to change set values.⑬ Press the indicator to start Automatic operation.⑭ Press the indicator to stop Automatic operation.⑮ Press the indicator to shift to Menu screen.⑯ Names of materials in individual hoppers are shown; the names can be registered via Recipe Setting.⑰ Weighing hopper is shown. The weight of material currently weighed is shown; once all materials are weighed, indication shifts to total weight display.Press the indicator to shift to Recipe pattern list screen.⑱ Mixing drum is shown. Mixing blade rotates during mixing operation and blinks if material is not yet discharged.Press the indicator to shift to Transport and mixing setting screen.

INVERTER CHILLER

KCW IV SERIES

●Operates with optimum cooling capacity

according to the load

●Energy saving

(Power consumption, 41-79% less than the

conventional model)

●Many lineups

(3HP~60HP)

●High compatibility with the conventional

model

※Machine dimensions and piping remain

the same

Eco Water System

ADA-2 LITTLE D

KAWATA Dehumidifying Drying Machines For Medical applications

DFC Series

All parts where the material contacts are stainless steel specifications

-

Comparison of molds with short shot defects due to mold stains when using the interceptor

Without Interceptor

(Use raw material : PBT)

With Interceptor

(Use raw material : PBT)

It has been proven that the interceptor is effective as a measure against mold stains.

Time and cost required for mold maintenance

These numbers may vary depending on your usage time and usage.

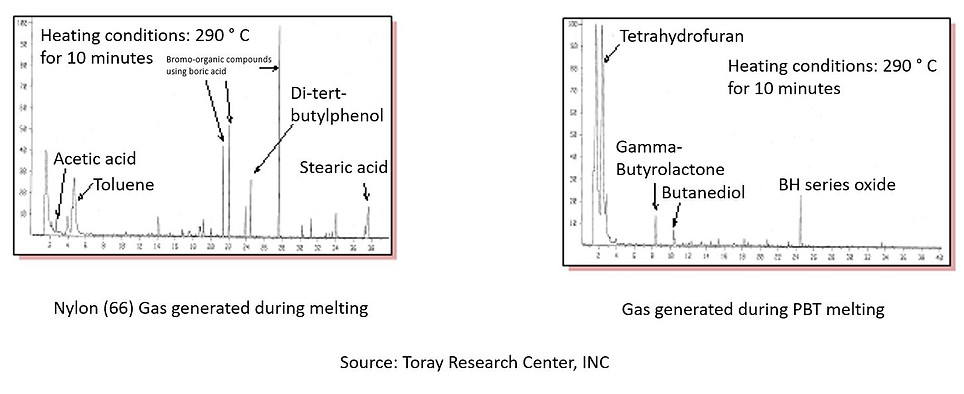

Analysis of gas generated when resin melts

Mold smudging or die fouling can be significantly reduced

-

M-STABILIZER-

<Stable Molding Technologies>

Photograph of an interceptor at a customer making auto parts in Georgia

Why manufacturers cannot produce products in the same way...

Why productivity differs depending on the region/equipment...

Why is it bad if the material contains water...

Why adding heat to the material in the dryer...

What can we do with Auxiliary equipment?

For stable molding to make quality products, we require a molding machine, a mold, and durable resin raw materials. Most of the causes of defects can figure out by the mold and the molding machine that we can assume. However, if the condition of the resin supplied to the molding machine is not stable, the production will not be steady. For example, if the resin's moisture content becomes unstable, the melt viscosity becomes unstable. Also, gas is generated, and the molding defects such as the silver streaks are caused. As a result, the molding conditions must be changed.

The only thing that plastic auxiliary equipment can do is stabilize the moisture level and stably supply materials with less dust, which is the most important thing.

So what are the factors that make it unstable?

The first is the storage condition of raw material tanks, etc. This is a part that is often overlooked.

The second is the conveying method from the dryer to the molding machine. Moisture may be absorbed immediately after conveying materials to use outside air.

The third is the residual materials inside of the molding machine or the piping.

The sealed raw material bag is stored at a constant moisture level. The condition will change immediately after opening. The graph is expressed with the image of nylon, which has high hygroscopicity, but other materials are also the same. It will change significantly depending on the environment in which it is placed.

The dew point goes up and down means that the content of caution changes depending on whether it is cold or hot. Also, if the dew point is close to 20 ° C, it will absorb moisture shortly.

What changes when the initial moisture is different is that the drying time and the reached moisture content will be change. A dryer is a device that can remove a certain amount of water in a certain time.

In other words, if the condition of the feeding material changes, the moisture content of the discharged material will change. Therefore, it may be one of the causes that silver streak suddenly occurs during continuous production, and the conditions become unstable. Excessive moisture causes silver streak, which is a problem, but if it is dried too much, the melt viscosity will increase, causing short shots and gas generation.

What is happening on the molding machine?

It cannot be dried to 0ppm with a dryer.

When you enter the barrel, which is hotter than the dryer, drying will be accelerated.

Then, the moisture that has no escape is exhausted from the material supply port.

In addition, conveying materials with outside air or undried air may cause moisture absorption, and it may stay in the piping and absorb moisture when it cools.

Furthermore, suppose materials stay in the molding machine hopper for a long time. In that case, they will cool down and be added alternately with the material immediately after drying, which is one of the causes of unstable melt viscosity.

If the initial moisture is not controlled, the condition of the material discharged from the dryer will change significantly. If the retention is long, the moisture content will change gradually.

Therefore, Kawata has some suggestions.

Next, there is the DO-series as a representative device of M-stabilizer technology.

Dry with nitrogen in a closed system.

Regarding nitrogen, we will generate nitrogen air inside the equipment by providing air from the customer.

The big difference from the conventional nitrogen dryer is that the drying air's nitrogen concentration is about 99%.

Besides, by using a closed nitrogen purge tank as the raw material tank, the condition does not change even if it is stored and conveyed.

As shown in the above figure, it is a method to separate the adhering powder while the materials turn around the particular filter part.

It is a continuous method in which materials are conveyed and supplied from the top.

Although it is small and compact, but it has excellent capabilities.

Also, large long film-like products such as floss cannot be removed.

High-performance Plastics Expo

2019 Technical description

DO Series

DT Series

XF Series

Drying device for optical film (It can be used for any type of LCD)

Xeno filter

XF series

Removes fine powder and foreign matter by centrifugal force improves forming trouble

-

High-efficiency removal of delicate powder / foreign matter by centrifugation using transport air as driving force

-

It can be installed on the equipment and the existing conveying hopper.

-

Easy to disassemble / clean with simple structure

We have the XENOFILTER at the Illinois office. If you would like to try this, please contact us.

XF Series

-

MTC Guide

JUSTTHERMO series

TW/160・180

Medium : Freshwater

Temperature: Max160・180℃ (320/356℉)

Best match for molding of electric molding machines, PPS, SPS, Ultem materials

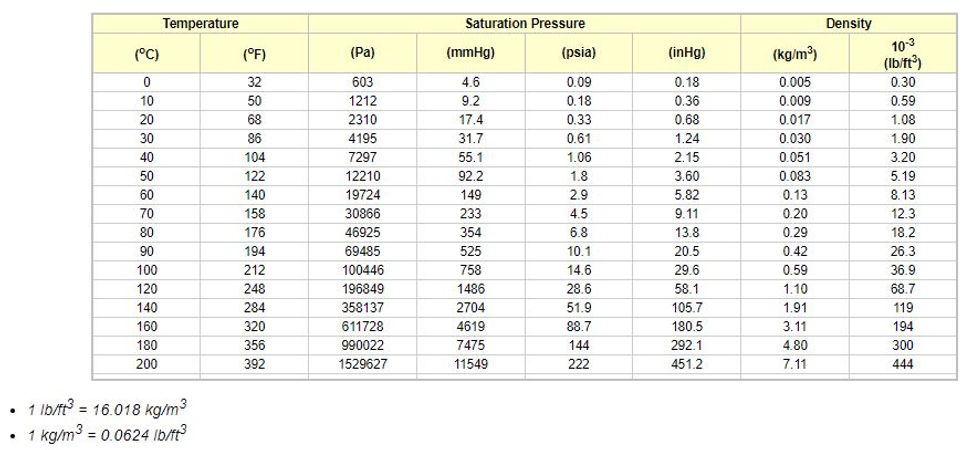

Adjusting the pressure brings the water to a high temperature

Saturated vapor state

Reference by engineeringtoolbox.com

Color Sort

High-Definition Color

Separator for Pellets

Related Products

Kawata Japan published the new model of the mold temperature controllers from IPF Japan.

Kawata Shanghai published the new model of the mold temperature controllers

Wind Brush

Easy filter cleaning is easy!

-

Easy automatic cleaning by air flow

-

It does not damage the filter

-

One-touch attachment and removal

VIDEO

The best energy saving is to reduce defects,

By reducing production loss and

Consider reducing throughput time.